|

The Synergistic Relationship of Energy and Storage Capacity/Space Savings

This week's blog post comes to us from one of our first Freezer Challenge supporters - Stirling Ultracold. Stirling Ultracold has been leading the industry in promoting energy-efficiency for years. In this post, Scott Masiella, Director of Product Management, explains how energy-efficiency combined with high-density storage can result in significant savings for labs. As a sustainability advocate and sponsor of the 2019 International Laboratory Freezer Challenge, Stirling Ultracold actively supports the Challenge’s core principles and sample management best practices. Our mutual goals are to reduce energy consumption, costs and environmental impacts in laboratories and facilities, and to optimize valuable floor space through effective utilization of ultra-low temperature (ULT) freezer storage capacity. Energy and Carbon Footprint Savings by Replacing Legacy Freezers When considering how to reduce lab energy usage and costs, one way is to replace older ULT freezers with new energy-efficient and ENERGY STAR®-certified units. If you consider the high average kWh/day energy consumption of legacy ULT freezers at current electricity rates, you’ll find significant cost savings opportunities that many facilities may be overlooking. As Freezer Challenge participants are well aware, both operating carbon footprint and energy use can be greatly reduced by replacing older, inefficient ULT freezers. Space Savings by Increasing Storage Density per Freezer Footprint However, as many research organizations expand their sample inventories, and may even be contemplating facility construction to accommodate their growing ULT storage needs, a greater premium is being placed on storage capacity per square foot/meter of floor space. As pointed out in last year's blog post, Increasing ULT Freezer Storage Capacity with Limited Space and Budgets, this involves a comparison of interior volume and exterior size specifications of various ULT freezer models. Purchasing a ULT freezer that has larger storage volume in the cabinet, yet has smaller exterior footprint dimensions, will save valuable floor space. If you factor in the value of the lab or biobank floor space cost per square foot/meter, along with the freezer storage capacity that needs to be replaced, a ULT freezer with the most storage volume per exterior footprint will create substantial floor space savings per year. An organization should also look at the sample storage capacity of current ULT freezers before beginning the costly process of expanding facilities or purchasing new replacement units. Lab managers and researchers should consider high-density storage and cell dividers. These solutions will allow researchers to maximize their available sample storage space. If you take full advantage of your freezers’ available storage capacity and utilize high-density storage systems (600 or 700 boxes with 100 cell dividers), you may be able to reach your needed storage capacity with fewer freezer units overall! Cost Synergies by Replacing ULT Capacity with High-Efficiency, High-Density Freezers ULT freezers with designed-in high-density storage further enable floor space and capital cost savings by allowing you to purchase fewer replacement freezers for the same sample storage capacity. Not only might expanded facilities not be necessary, but freezers that combine energy savings with high-density storage savings create an even greater benefit by reducing energy, maintenance and infrastructure costs over a lifetime of operating fewer freezer units. These elements have a synergistic relationship that will give you a better return on your investment. It will take fewer years to get the initial investment back on new energy-efficient ULT freezers if high-density storage is also implemented to reduce floor space and number of units purchased, based on storage capacity requirements. These best practices are at the foundation of the Freezer Challenge objectives. When making these energy and space savings decisions, don’t hesitate to contact your freezer provider for assistance. There are tools available to help calculate energy, space and operating cost savings from replacement of legacy models.

5 Comments

The Importance of ENERGY STAR

This week we are excited to bring you a blog post from Joe LaPorte, Director, Product Group at PHC Corporation of North America. Joe is one of the most knowledgeable people we know about freezers; he has been working with ENERGY STAR for over a decade on standards for laboratory units. The International Laboratory Freezer Challenge is made possible due to the generosity of our sponsors. We are incredibly grateful to PHC for supporting the Freezer Challenge at the Gold level, and to Joe for sharing this thoughts on ENERGY STAR below: Since Energy Star was first introduced for the laboratory grade products category in late 2017, many who purchase new ultra-low freezers have begun to rely on the ENERGY STAR data for input in their buying decisions. The ENERGY STAR website section related to laboratory freezers and refrigerators provides detailed information about energy performance that can be expected under real world operating conditions. While the information is accurate, most purchasers, however, do not know how these overall energy consumption models are calculated. Since end users typically operate their freezers at -80°C or -70°C (or within this range) these calculations include energy consumption at both temperatures. Furthermore, since many freezers are accessed multiple times a day, the ENERGY STAR profile at both temperatures is based on 6 door openings during an 8 hour period. A simulated product load representing typical use patterns was developed under consultation with the Department of Energy, qualified ultra-low freezer manufacturers and end users. ENERGY STAR testing is conducted on empty freezers. Usage patterns vary from one installation to the next. This is why the ENERGY STAR evaluation is independently conducted by EPA licensed testing laboratories in an effort to assure an accurate ‘apples-to apples’ comparison of different models and freezer brands. Additionally, most end users are interested in other performance criteria such as temperature recovery after door openings and interior uniformity in the steady state, both of which contribute to the overall performance profile of an ultra-low freezer. Thus, in addition to the ENERGY STAR testing criteria focused mostly on power consumption, the independent testing agency typically provides client manufacturers with a full data set on how ultra-low freezers published in the ENERGY STAR certification schedule performed beyond the minimal specification. An informed decision in advance of an ultra-low temperature freezer purchasing decisions requires examination of this data provided by both ENERGY STAR and the manufacturer. |

Archives

May 2021

Categories |

The Freezer Challenge is a program coordinated by the non-profit organizations

My Green Lab® and the International Institute for Sustainable Laboratories, and sponsored by various companies with an interest in promoting the most energy efficient cold storage options.

My Green Lab® and the International Institute for Sustainable Laboratories, and sponsored by various companies with an interest in promoting the most energy efficient cold storage options.

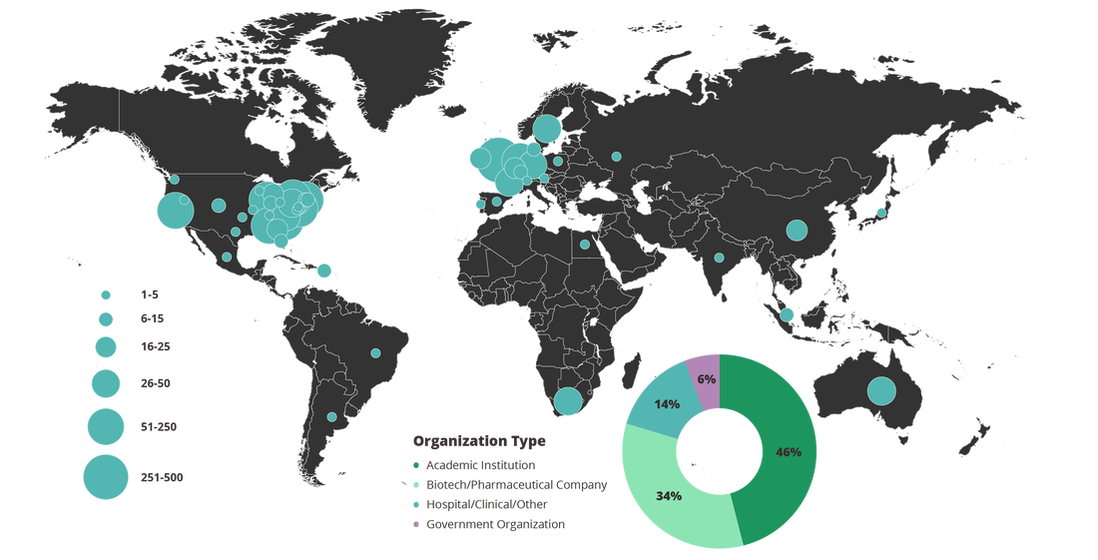

Global Reach of the 2023 International Laboratory Freezer Challenge

RSS Feed

RSS Feed