|

There are five weeks left in the 2020 International Laboratory Freezer Challenge, and we hope the past six months has given your lab ample opportunity to assess your cold storage practices, become more energy efficient, and protect your research samples. If your laboratory has already finishing documenting their sustainable actions on the Freezer Challenge scoresheet, feel free to submit it early. Otherwise, be sure to get your scoresheet in by midnight on August 1. Don't forget to submit your scoresheet, because winning the Freezer Challenge comes with some amazing perks! If your lab wins one of the individual categories or your institution wins one of the organizational categories, you get your photo in Nature this fall, plus you will be recognized at the International Institute for Sustainable Labs Annual Conference in October.

For a bit of nostalgia, and to spur on the competition, check out the laboratories and institutions that won the Freezer Challenge in 2019 and were featured in Nature. If you don't know how to access your scoresheet, please email [email protected].

3 Comments

Laboratory cold storage can be downright surprising. Did you know:

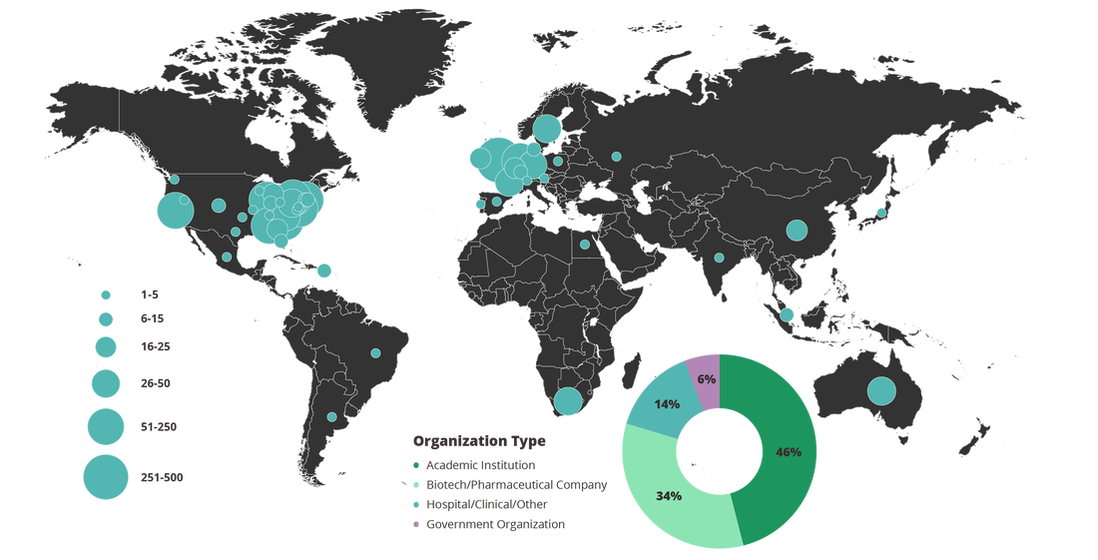

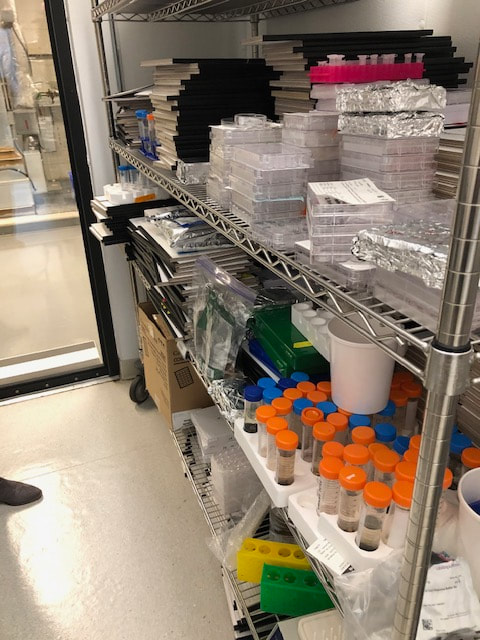

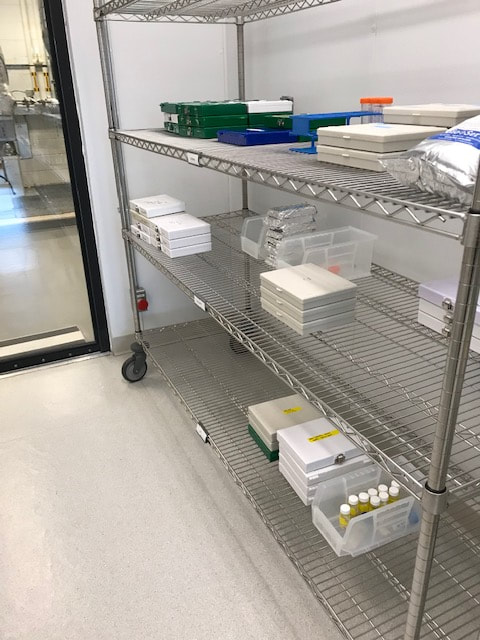

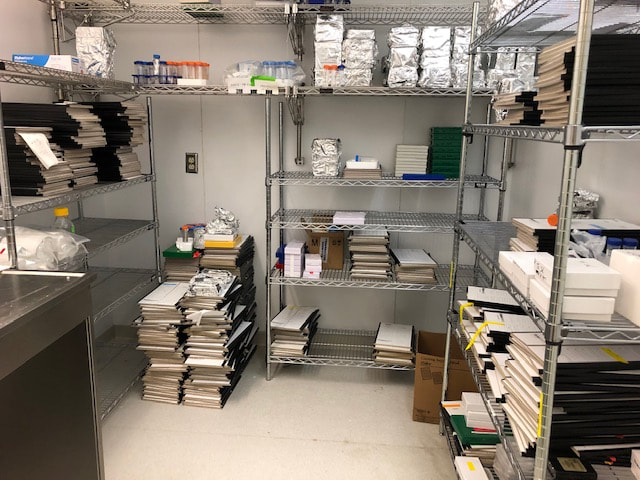

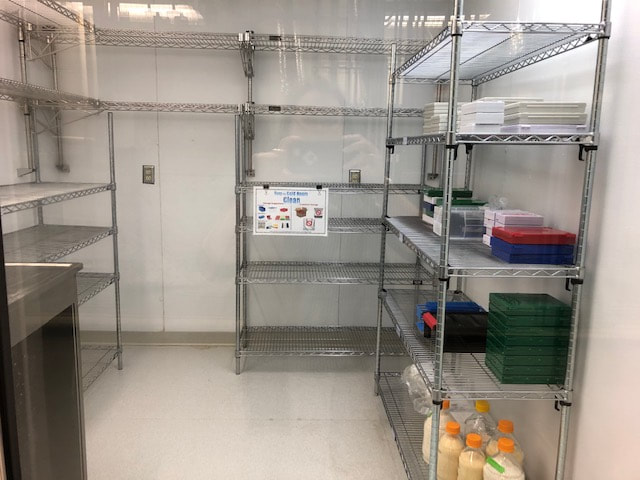

You are a part of a worldwide community of scientists working to make cold storage more efficient and less energy intensive. As of today, over 85 organizations are participating in this year's International Laboratory Freezer Challenge, representing over 200 labs! This is a 112% increase in the number of organizations that were engaged in the Challenge in 2019!! Keep up the amazing work as we move into the last 6 weeks of the 2020 Freezer Challenge. Reminder: The deadline for this year's Freezer Challenge is now August 1, 2020. This is a guest blog post submitted by the Lab Coordinator Team (pictured above) at HHMI's Janelia Research Campus, who are participating in this year's Freezer Challenge. A recent initiative at the HHMI Janelia Research Campus has scientists and administrative/building operations working together to clean out 22 cold rooms. Janelia’s ‘open science’ model translates into shared and open laboratory spaces throughout the building, including shared ownership of the cold rooms. Since opening in 2006, the Janelia community has grown to more than 800 employees and contractors, and the increased use of the cold rooms has resulted in many becoming overcrowded and in desperate need of cleaning. Prior to the COVID-19 shutdown, 2 of the 22 cold rooms had been tackled using the following approach. Multiple factors led to a crisis in the cold room conditions. Labs that departed Janelia left behind old slides and materials, and many lab materials have been retained unnecessarily post-publication. In addition, unsuitable cold room storage solutions have been used for many years, resulting in mold growth and damage to research materials. After a survey we determined that some would need minimal cleaning while others would require full decontamination. Seeing this need, our Lab Coordinator (LC) Team literally put on our winter coats and stepped in to take on this initiative. The LC Team, while not traditional lab managers, provides administrative support to the labs acting as a liaison between science and operations removing administrative barriers in order to ensure our labs can focus on their science. Traditionally, each LC works closely with four to eight Janelia labs. Here's how we tackled one of our largest projects to-date. After numerous meetings to gather feedback with various stakeholders - Facilities, Housekeeping, Safety Health & Security (SH&S), Communications, Shared Resource Managers and Senior Leadership - the LC Team developed a plan of action. Our intent was to make the process as simple as possible to have minimal impact on our scientists’ schedules. The process also needed to be sustainable long-term and incorporated into our regular work schedule for the next ~16 months. Advance planning is critical for cold room cleaning & organization Timing & Scheduling: Three weeks were allotted for each cold room cleaning. One week to advertise and plan what resources and repairs will be needed for each room; one week to empty, discard, and transfer items; and one week to return the samples to the room in containers appropriate for cold storage. Meetings: Using a checklist developed by the LC Team, we delegated key tasks and had regular meetings to stay on schedule. Creative Advertising: We advertised cold room cleanings to generate enthusiasm and sustain momentum throughout the initiative. Supplies: Pre-ordered appropriate storage containers: plastic vial rack holders of all sizes, light-blocking containers for sensitive samples/reagents, and plastic slide cases. Large rolling carts with plastic ware, gloves, cleaning supplies, slide cases, etc. were positioned outside the cold room for easy access along with chemical disposal bins, biohazard boxes, and two temporary refrigerators. Cleaning Process: Lab members went through their inventory to dispose of unneeded samples/reagents and reorganize remaining samples in new storage containers, using the temporary alternate refrigerators to do this so the cold room was completely empty. With SH&S’s help, a contractor decontaminated the room. Then the facilities team took care of necessary repairs and housekeeping did a heavy-duty cleaning of the floors and racks. We labeled shelving and installed signage before samples were placed back in the cold room. Post Clean Out: Easy to read signage with details of the accepted ways to store samples were posted in the room. Going forward, annual safety inspections performed by our SH&S team will monitor storage in the room and identify areas that need addressing. Recognition: Celebrate accomplishments! After each clean out (two have been completed to-date), we thanked the team and the scientists involved using institution wide communications. There is nothing more gratifying than posting before and after pictures as they have a huge impact! Marie Kondo would be so proud!

By focusing on our cold rooms, here are some of the benefits we’ve already seen:

Written by Victoria Custard, Laura Hart, Alison Howard, Anastasia Osowski, Melanie Radcliff, and Kerry Sobieski at HHMI’s Janelia Research Campus Reminder: the new deadline for the Freezer Challenge is August 1st! What are HFCs?

HFCs, or hydrofluorocarbons, are a class of potent greenhouse gases that are commonly used in refrigeration systems, air-conditioning units, building insulation, fire extinguishing systems, and aerosols. They have come into use as a replacement for other chemicals that are ozone-depleting, but HFCs pose issues of their own. Namely, they have a high global warming potential (GWP) - anywhere from 1,000 to 9000 times greater capacity to warm the Earth's atmosphere than carbon dioxide. Since HFCs are still common, they might be in your laboratory's cold storage units....refrigerators, freezers, and cold rooms. Managing cold storage isn't just about the kWh Better refrigerant management worldwide is one of the top ten most impactful climate change solutions in terms of gigatons of carbon dioxide reduced/sequestered according to Project Drawdown. "Refrigerant Management" means avoiding leakage of refrigerants into the atmosphere and the effective destruction of refrigerants at their end of life, which worldwide could reduce carbon dioxide emissions by approximately 57 gigatons by 2050. Managing refrigerants in these ways has a much larger impact on mitigating climate change than recycling, electric cars, geothermal power, or rooftop solar. This analysis was done by a team of climate scientists and published in 2017 in the eye-opening book Drawdown, with analysis revisions on the Project Drawdown website. What can you do as part of the Freezer Challenge to reduce the impact of HFCs? If you're retiring a freezer this year, take an interest in its end of life. Ask your facilities management team or equipment recycling team how the refrigerants are being removed, and inquire into what will happen to the refrigerants next. Furthermore, make sure your freezer is disposed of expeditiously - you don't want it to start leaking! If your lab is purchasing a new freezer, avoid purchasing units that contain HFCs. It doesn't matter how inexpensive they are, just don't buy them. There are laboratory freezer options now that use 100% natural refrigerants, which are a small fraction of the global warming potential of HFCs, often involving hydrocarbons or helium. Ask your preferred supplier or cold storage manufacturer if they use natural refrigerants in their products! Reminder: the new deadline for the Freezer Challenge is August 1st! The International Laboratory Freezer Challenge is run by the non-profits My Green Lab and I2SL and is supported by our generous sponsors: Eppendorf, Stirling Ultracold, PHCbi, and Thermo Fisher Scientific. Photo credit to Curioso Photography via Unsplash |

Archives

May 2021

Categories |

The Freezer Challenge is a program coordinated by the non-profit organizations

My Green Lab® and the International Institute for Sustainable Laboratories, and sponsored by various companies with an interest in promoting the most energy efficient cold storage options.

My Green Lab® and the International Institute for Sustainable Laboratories, and sponsored by various companies with an interest in promoting the most energy efficient cold storage options.

Global Reach of the 2023 International Laboratory Freezer Challenge

RSS Feed

RSS Feed