|

Laboratories around the world have been impacted to varying degrees over the past several months. For some, you may just be getting back into the lab, with your lab operating at reduced capacity. As a result, we've made the decision to extend the Freezer Challenge deadline to August 1, 2020. Please submit your scoresheets by then!

As May fades to June and July, we'd like to see how your lab is participating in the International Laboratory Freezer Challenge through some photos! With permission from all lab members pictured, we'd appreciate it if you would share photos with us of your lab working on defrosts, sample clean-outs, inventorying, or preventative maintenance on cold storage units. Either post these directly to social media and tag My Green Lab, or email them to us at [email protected] for us to share. Do this anytime between now and August 1st. Each laboratory that shares a photo(s) with us will receive an extra point on their Freezer Challenge scoresheet! In this way you are helping us raise further awareness of the Freezer Challenge and the many positive impacts it can have in a laboratory, including improved sample integrity and energy efficiency. Find My Green Lab on Twitter, Facebook, LinkedIn, and Instagram. Or simply email us your photo! The Freezer Challenge is run by the non-profits My Green Lab and I2SL and is supported by our generous sponsors: Eppendorf, Stirling Ultracold, PHCbi, and Thermo Fisher Scientific.

2 Comments

In July 2014, six vials of smallpox virus were discovered in an unsecured cold room on the NIH campus in Bethesda, Maryland by a FDA scientist. Further investigation determined that the vials did indeed contain live virus and had not been known to the FDA or NIH for roughly 50 years, the length of time they had been sitting in storage. This situation sheds light on one of the more extreme risks of a lack of biological sample inventory, but there are a multitude of benefits to having accurate and efficient sample inventory management too. From safety and security to energy efficiency and time savings, having a high-quality inventorying management method is the way to go. Claudio Rolli of FLUICS GmbH in Germany wrote the following guest blog post about sustainable inventory management. Samples that are stored in your refrigerators, freezers, and cryo-storage are unique and precious. It is either a lot of effort to produce or collect them, or they are expensive to buy. Typically, many different reagents such as buffers and purification resins, as well as consumables like tubes, tips, and flasks are needed to prepare the bio-samples before they finally make their way to long-term storage. Also, for ethical reasons, one is advised not to waste human or animal derived samples such as biopsies and blood that are used for cell cultures or extraction of antibodies. Storing biological samples under frozen condition consumes significant energy. For example, a single ultra-low temperature freezer running at -80 ºC consumes as much electricity as a household of four. The actual energy consumption also depends on how often and for how long the freezers are opened as well as how much ice is allowed to accumulate inside – a result of condensation which decreases the efficiency of cooling and increases the total energy consumption. Therefore, labs should only fill their storage spaces with well-labeled samples instead of jamming them up with poorly labeled or even outdated material. Two main attributes of your samples should be considered to quickly find what you are looking for within cold storage units, reducing excessive energy consumption:

Comparison of mobile inventory management vs. traditional databases Traditional Databases

Mobile Inventory Management

Keeping a lab's sample inventory up to date is key for reducing the number of needed freezers, minimizing excessive energy consumption from repeatedly opening cold storage units, and efficiently using valuable cold storage space in the lab. To learn more about mobile inventory management and QR codes for samples visit the FLUICS CONNECT website. Written by Dr. Claudio Rolli, FLUICS GmbH, 80333 Munich, Germany [email protected] The deadline for the Freezer Challenge is July 1st! The Freezer Challenge is run by the non-profits My Green Lab and I2SL and is supported by our generous sponsors: Eppendorf, Stirling Ultracold, PHCbi, and Thermo Fisher Scientific. How much thought have you given to the size of the tube you use for your samples? Or the size of your storage container? This guest blog post from Micronic highlights how carefully considering these simple choices can have a significant impact on your lab’s cold storage.

The validity of the data of a research project depends on the quality of samples. To prevent reductions in quality, strict standards for sample storage are needed. This is where the standardization of biobanking practices can be useful. But how should you standardize efficiently? Determine tube size Samples should be placed in tubes corresponding the volume of the sample. When sample volume has been estimated based on the research protocol, the next step is determining appropriate tube size. To increase storage efficiency and minimize sample loss, avoid excess volume inside the sample storage tube. Arrange tubes To increase long-term sample storage efficiency, evaluate how your tubes are arranged within storage containers. Placing tubes into well-organized, robust storage racks or boxes that comply with the ANSI/SLAS standards and then stacking these efficiently in aluminum freezer racks optimizes the number of samples that can be stored in a freezer or cryo tank. This saves space, enabling you to store more within the unit. Ensure traceability Each sample tube and storage rack should be coded to ensure that every sample is traceable at any given moment. A common way to code sample storage tubes and racks is with text and barcodes, most secure by etching with a laser. By scanning the barcode of each tube and rack, each sample can be easily registered or updated. The location and characteristics of a sample should be recorded carefully in a Laboratory Sample Management System so it can be found again when that sample is needed for further research. By scanning barcodes of samples as they leave the freezer, this ensures the absolute traceability of each sample. Special thanks again to Micronic for sharing this information with us! This guest blog post was written by Irina Choulguina, Marketing Specialist at Micronic As a reminder, the deadline for the Freezer Challenge is now July 1! Though we paused the blog for the past few weeks, the International Laboratory Freezer Challenge is still ongoing...in fact, we extended the deadline to July 1, 2020! As of today there are two months left in which you can still take action with your lab's cold storage to improve energy efficiency and sample integrity, saving your lab time and money. Just be sure to get those scoresheets in by July 1.

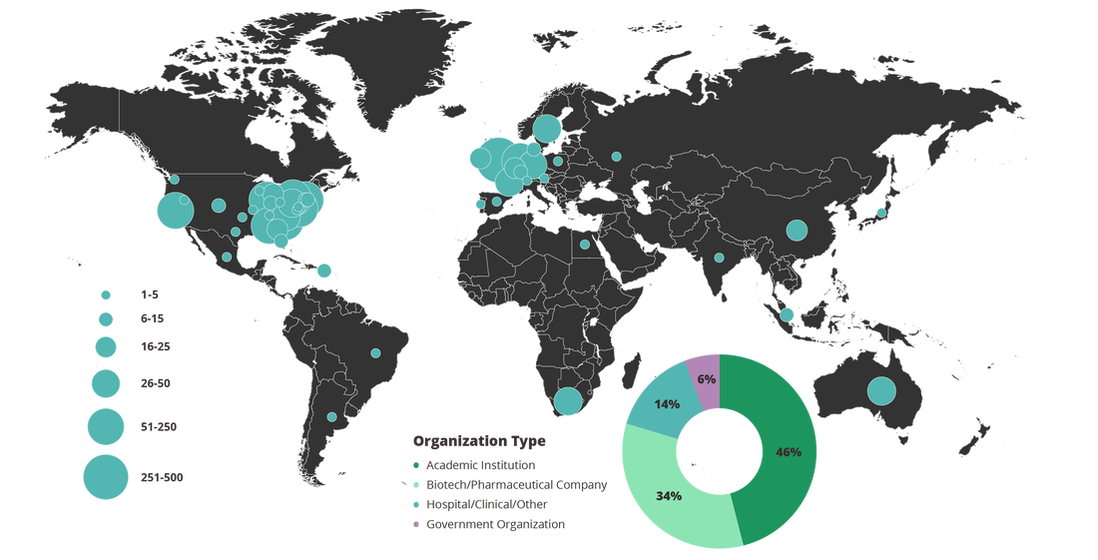

We are thrilled with the enthusiasm and engagement we have received for the Freezer Challenge this year - over 90 organizations worldwide are participating. Thank you for being a part of this fun, competitive opportunity to address storage in your lab's refrigerators, freezers, and cold rooms. Many laboratories are now aiding the global effort to combat COVID-19. In case you haven't seen it, we wanted to share the CDC's Laboratory Biosafety and COVID-19 FAQ, which includes guidelines for sample storage of COVID-19: "Store specimens at 2-8 ºC for up to 72 hours after collection. If a delay occurs in extraction, store specimens at -70 ºC or lower. Store extracted nucleic acid samples at -70 ºC or lower." This aligns with our adage of "-70 really is the new -80 C"! It's wonderful to see the CDC's guidelines mirroring the recommendations of the Freezer Challenge. Be well! The Freezer Challenge is run by the non-profits My Green Lab and I2SL and is supported by our generous sponsors: Eppendorf, Stirling Ultracold, PHCbi, and Thermo Fisher Scientific. Photo by Immo Wegmann on Unsplash |

Archives

May 2021

Categories |

The Freezer Challenge is a program coordinated by the non-profit organizations

My Green Lab® and the International Institute for Sustainable Laboratories, and sponsored by various companies with an interest in promoting the most energy efficient cold storage options.

My Green Lab® and the International Institute for Sustainable Laboratories, and sponsored by various companies with an interest in promoting the most energy efficient cold storage options.

Global Reach of the 2023 International Laboratory Freezer Challenge

RSS Feed

RSS Feed