|

Increasing ULT Freezer Storage Capacity with Limited Space and Budgets This week we're excited to feature a guest contributor to our blog! This post comes from Timothy Root, Director of Marketing at Stirling Ultracold, the Platinum Sponsor of the 2018 Freezer Challenge. Read below to learn how to increase storage capacity in spite of limited resources. And don't forget, the Freezer Challenge deadline has been extended to June 15th. With growing inventories of biological samples often stored in cramped spaces of today's laboratories and biorepositories, the first reaction might be to build or renovate research facilities when there is a need to increase ultra-low temperature (ULT) storage. This can be an expensive and sometimes impractical option that may not even be necessary, considering other viable alternatives. What is ULT “High-Density Storage”? There are cost-effective ways to significantly increase ULT storage capacity within your current space limitations, including several core principles being practiced in the International Laboratory Freezer Challenge. As an alternative to investing in disruptive facility renovations and expansions, smart research organizations are choosing to practice “high-density storage” within their available floor space. This approach supports growth in vital assets needed for research, while conserving funds that could be applied more directly to curing disease. Following last month’s Freezer Challenge blog post about using high-density racks and boxes, let's look at some other proven options for enhancing ULT storage density. Efficient Sample Management Practices As many Freezer Challenge participants have found, a surprising volume of underutilized ULT storage capacity is already hidden within your current lab facilities. A comprehensive review of sample inventories and sample management processes will almost certainly reveal sample misplacement, redundancy, obsolescence and wasted storage capacity. For example, it's common practice in research organizations to "manage" samples by dedicating ULT freezers by owner, department, date range, project, etc. This divides sample storage capacity unnecessarily, wasting a significant amount of energy, capital cost and floor space. By implementing best practices, such as electronic inventory management and 100-sample boxes, ULT freezer storage density can be significantly optimized, while also improving your ability to organize and retrieve samples. This approach helped last year’s North American Freezer Challenge participants consolidate an estimated 66 freezers. Freezer Placement and Layout Another option to explore for maximizing ULT storage floor space is optimal placement of freezers in a given space. To make the most of your floor space, refer to manufacturer specifications for minimum clearances required for your model. This includes minimum clearances between freezers, door swings and against walls. It’s important to consider the minimum rear wall clearance required for the ventilation of your freezer, as not all freezers are the same. To optimize placement of multiple freezers, a layout should be prepared that considers accurate freezer footprint dimensions, minimum clearances, interior ventilation, ergonomic and safety considerations for your defined space. In general, side-by-side placement of freezers across the long axis provides the most efficient use of space. If space allows multiple rows, using minimum door swing clearances will also help optimize space. Whether in a linear, matrix or irregular arrangement, a smaller freezer footprint may be key to enhancing ULT storage density when it allows an incremental increase in freezer units to be placed within the same floor space. Freezer Design Advantages for High-Density Storage Another very important consideration for maximizing ULT storage capacity in a defined space is the design of the freezer itself. The ratio of a freezer's cabinet storage volume (ft3/liters) to its footprint area (ft2/m2) determines the "storage density” designed into your ultra-low freezer model. A critical design factor affecting the volume/footprint ratio is the amount of cabinet volume not available for ULT storage. A freezer design that devotes less space to housing mechanical systems can devote additional interior cabinet volume to storing more samples per square foot/meter of floor space. A combination of high-density storage practices, freezer placement and space-efficient freezer cabinet design can substantially expand your ULT sample storage capacity without the disruption and high cost of facility renovation or new construction.

2 Comments

Is Your -20 Freezer Really a ULT Freezer? We've been conducting a study on the energy consumption of -20C freezers, and during our field research we've found quite a few ULT freezers set to -20C. That got us thinking: how much more energy does a ULT freezer set to -20 use than a typical -20C freezer? And while the data we've collected are still preliminary, it looks like it's 5 - 10x more. Yikes. Setting your ULT freezer to -70C is a great idea; setting your ULT freezer to -20C probably isn't the most efficient way to store samples at that temperature. If you're wondering if your ULT freezer is masquerading as a -20 freezer, just check the nameplate. Most ULT model numbers start with 'ULT', and most ULT nameplates are on the outside of the freezer. Minus 20 freezer model numbers do not include the letters 'ULT', and their nameplates are typically located on the inside of the freezer. And if you do find out that your -20 freezer is actually a ULT, you may want to consider a freezer swap with someone else in the department, or find a colleague willing to share space in their freezer. You may even be able to work with facilities management to purchase a commercial freezer - the energy savings from unplugging that ULT would make the payback 1-2 years. Refrigerants 101

Our post this week is courtesy of Denis Livchak from Frontier Energy. Denis is a refrigeration expert, and in his post below he explains the different types of refrigerants used in refrigeration systems, and why it's so important to pay attention to refrigerants. All refrigeration equipment contains refrigerant. Refrigerant is a substance that cools down the inside of the fridge or freezer by changing from gas to liquid and vice versa during a refrigeration cycle. Although there are several properties of refrigerants, from an environmental perspective the most important ones are global warming potential (GWP), ozone depletion potential (ODP) and flammability. Why are ODP and GWP so important if the refrigerant stays inside the refrigeration system? Because refrigeration systems leak. These leaks may occur through refrigerant piping contraction/expansion at different welds. through system recharging, or during disposal. Federal regulations have tried to minimize global warming and ozone depletion through mandating refrigerants that are more environmentally friendly with low GWP and ODP potential. Older refrigerants that are currently being phased out include R12 (also known as freon) and R22. These refrigerants have GWP values of 10,900 and 1,810 and ODP values of 0.82 and 0.06, respectively. The rule of thumb with GWP and ODP values is the higher the number, the worse it is for the environment. Nowadays these refrigerants are quite rare. Most modern refrigerants are zero ODP, however refrigeration units older than 20 years may still use R12 or R22. Most modern lab-grade freezers use R404A refrigerant, which has a GWP of 3,920. Ultra-low temperature freezers also use R508B as the secondary refrigerant, which has a GWP of 13,396. Natural refrigerants are the most environmentally-friendly option. Natural refrigerants include propane (R290), CO2 (R744) and ammonia (R717), and all have zero ODP and almost zero GWP. So why are we not using natural refrigerants in our equipment? There are drawbacks to each of the three: propane is flammable, CO2 requires very high pressure piping, and ammonia is poisonous. With technological advancements, refrigeration engineers have been able to minimize the risks associated with each type of refrigerant. The most prevalent natural refrigerants in laboratory refrigeration are propane (R290), and ethane (R170) for ultra-low temperature applications. By using small quantities of refrigerant, manufacturers have been able to minimize the potential flammability of the system while drastically reducing the global warming potential of refrigeration systems. Manufacturers are also required to perform safety testing to demonstrate that even a large leak of refrigerant in the freezer will not cause a fire. Energy testing has also proven that freezers with natural refrigerants consume significantly less energy. If you are not sure what kind of refrigerant your freezer uses, try checking the nameplate - it should be clearly labeled on there. And if you find that it's time to upgrade to a freezer with natural refrigerants, make sure you use an EPA-certified refrigerant reclaimer when disposing of the old unit. The Freezer Challenge Deadline has been Extended to June 15th! But this isn't an invitation to procrastinate - it's an opportunity to complete more of the score sheet, invite your colleagues to participate, and score more bonus points. We'll continue to keep you updated through our blog and social media. And don't forget, if you missed the webinar on 'Beyond Power Consumption: Storing Efficiently at -80C' you can download it and listen to it here. |

Archives

May 2021

Categories |

The Freezer Challenge is a program coordinated by the non-profit organizations

My Green Lab® and the International Institute for Sustainable Laboratories, and sponsored by various companies with an interest in promoting the most energy efficient cold storage options.

My Green Lab® and the International Institute for Sustainable Laboratories, and sponsored by various companies with an interest in promoting the most energy efficient cold storage options.

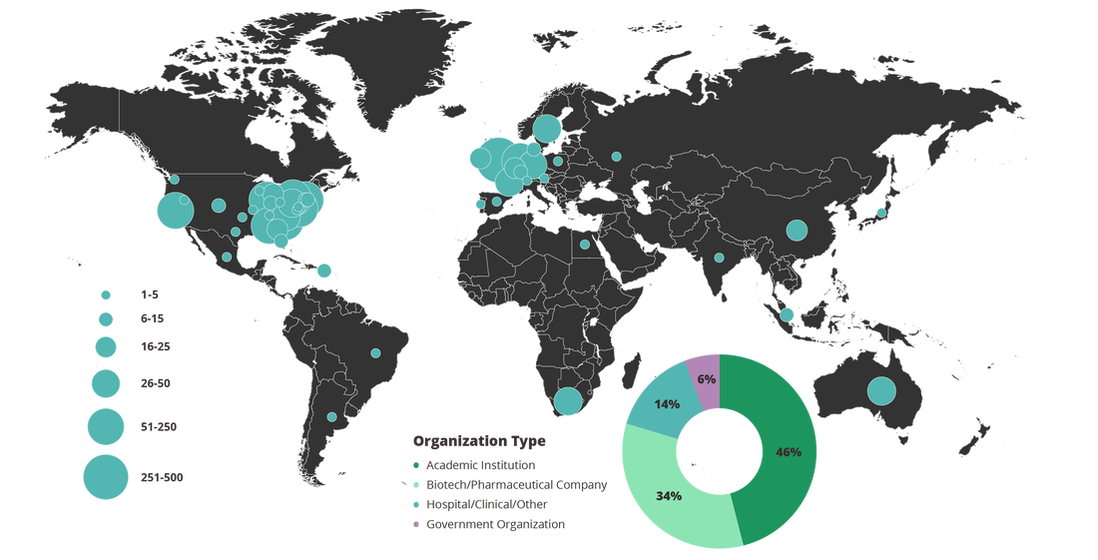

Global Reach of the 2023 International Laboratory Freezer Challenge

RSS Feed

RSS Feed