|

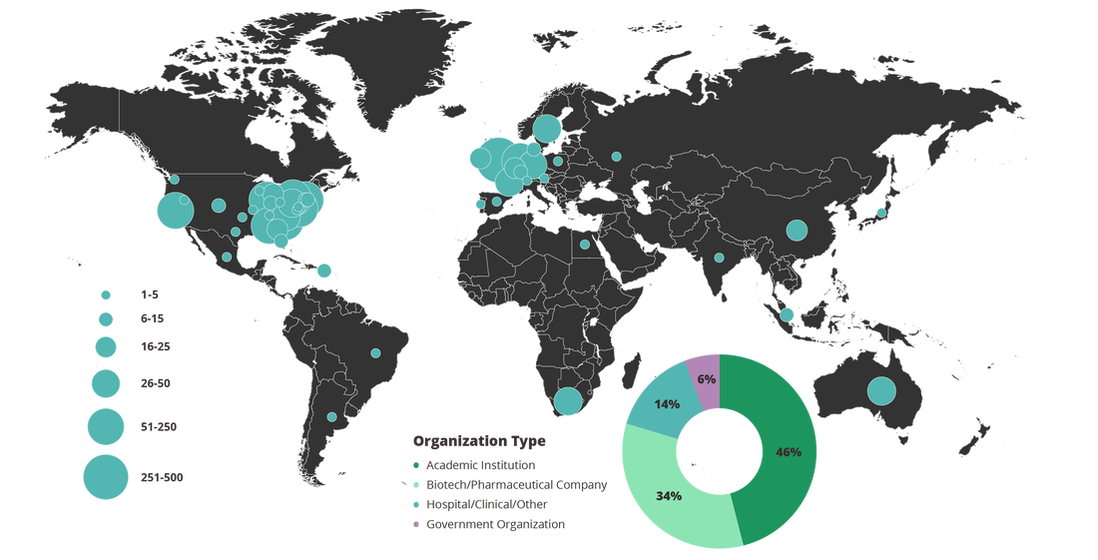

Increasing ULT Freezer Storage Capacity with Limited Space and Budgets This week we're excited to feature a guest contributor to our blog! This post comes from Timothy Root, Director of Marketing at Stirling Ultracold, the Platinum Sponsor of the 2018 Freezer Challenge. Read below to learn how to increase storage capacity in spite of limited resources. And don't forget, the Freezer Challenge deadline has been extended to June 15th. With growing inventories of biological samples often stored in cramped spaces of today's laboratories and biorepositories, the first reaction might be to build or renovate research facilities when there is a need to increase ultra-low temperature (ULT) storage. This can be an expensive and sometimes impractical option that may not even be necessary, considering other viable alternatives. What is ULT “High-Density Storage”? There are cost-effective ways to significantly increase ULT storage capacity within your current space limitations, including several core principles being practiced in the International Laboratory Freezer Challenge. As an alternative to investing in disruptive facility renovations and expansions, smart research organizations are choosing to practice “high-density storage” within their available floor space. This approach supports growth in vital assets needed for research, while conserving funds that could be applied more directly to curing disease. Following last month’s Freezer Challenge blog post about using high-density racks and boxes, let's look at some other proven options for enhancing ULT storage density. Efficient Sample Management Practices As many Freezer Challenge participants have found, a surprising volume of underutilized ULT storage capacity is already hidden within your current lab facilities. A comprehensive review of sample inventories and sample management processes will almost certainly reveal sample misplacement, redundancy, obsolescence and wasted storage capacity. For example, it's common practice in research organizations to "manage" samples by dedicating ULT freezers by owner, department, date range, project, etc. This divides sample storage capacity unnecessarily, wasting a significant amount of energy, capital cost and floor space. By implementing best practices, such as electronic inventory management and 100-sample boxes, ULT freezer storage density can be significantly optimized, while also improving your ability to organize and retrieve samples. This approach helped last year’s North American Freezer Challenge participants consolidate an estimated 66 freezers. Freezer Placement and Layout Another option to explore for maximizing ULT storage floor space is optimal placement of freezers in a given space. To make the most of your floor space, refer to manufacturer specifications for minimum clearances required for your model. This includes minimum clearances between freezers, door swings and against walls. It’s important to consider the minimum rear wall clearance required for the ventilation of your freezer, as not all freezers are the same. To optimize placement of multiple freezers, a layout should be prepared that considers accurate freezer footprint dimensions, minimum clearances, interior ventilation, ergonomic and safety considerations for your defined space. In general, side-by-side placement of freezers across the long axis provides the most efficient use of space. If space allows multiple rows, using minimum door swing clearances will also help optimize space. Whether in a linear, matrix or irregular arrangement, a smaller freezer footprint may be key to enhancing ULT storage density when it allows an incremental increase in freezer units to be placed within the same floor space. Freezer Design Advantages for High-Density Storage Another very important consideration for maximizing ULT storage capacity in a defined space is the design of the freezer itself. The ratio of a freezer's cabinet storage volume (ft3/liters) to its footprint area (ft2/m2) determines the "storage density” designed into your ultra-low freezer model. A critical design factor affecting the volume/footprint ratio is the amount of cabinet volume not available for ULT storage. A freezer design that devotes less space to housing mechanical systems can devote additional interior cabinet volume to storing more samples per square foot/meter of floor space. A combination of high-density storage practices, freezer placement and space-efficient freezer cabinet design can substantially expand your ULT sample storage capacity without the disruption and high cost of facility renovation or new construction.

2 Comments

3/10/2024 09:57:19 pm

Your recent blog post was a genuine treasure trove of insightful ideas and engaging anecdotes. Your unique writing style, infused with wit, evocative descriptions, and inventive analogies, brought the topic to life in my mind's eye. It felt as though I was accompanying you on the adventure, and I'm excitedly looking forward to your next blog post. I'll be keeping a keen eye out for it.

Reply

Leave a Reply. |

Archives

May 2021

Categories |

My Green Lab® and the International Institute for Sustainable Laboratories, and sponsored by various companies with an interest in promoting the most energy efficient cold storage options.

RSS Feed

RSS Feed